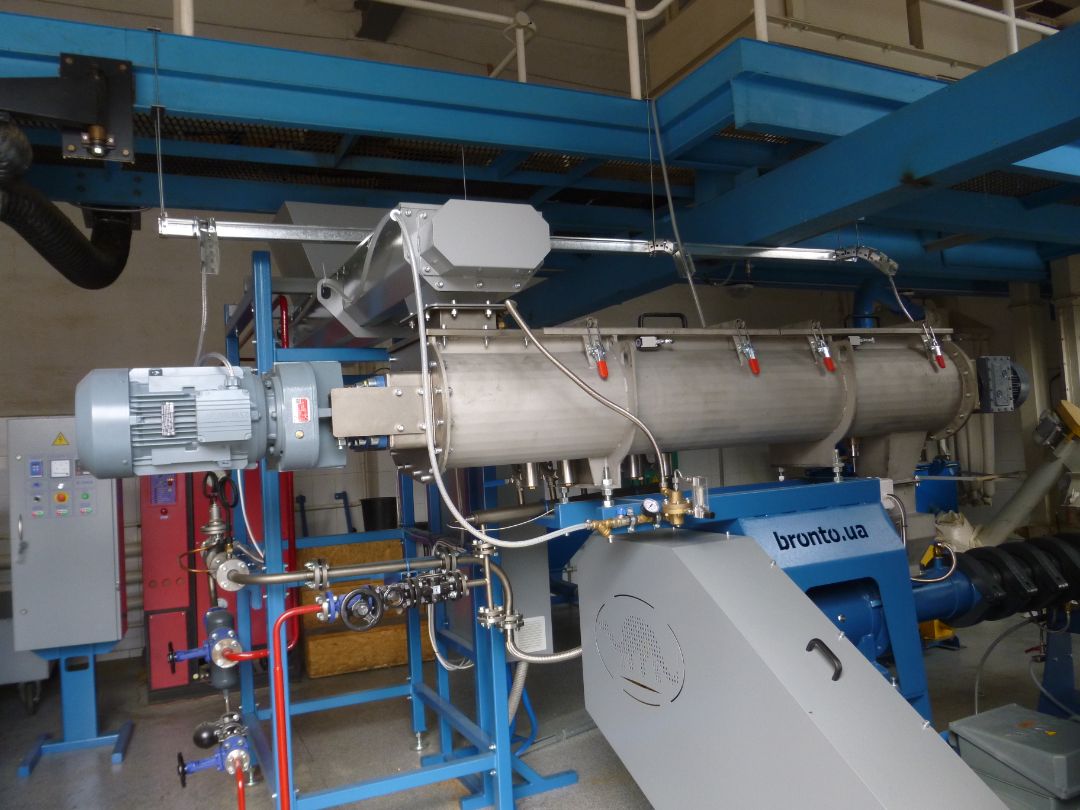

MANUFACTURER:

CherkasyElevatorMash Ltd TM BRONTO

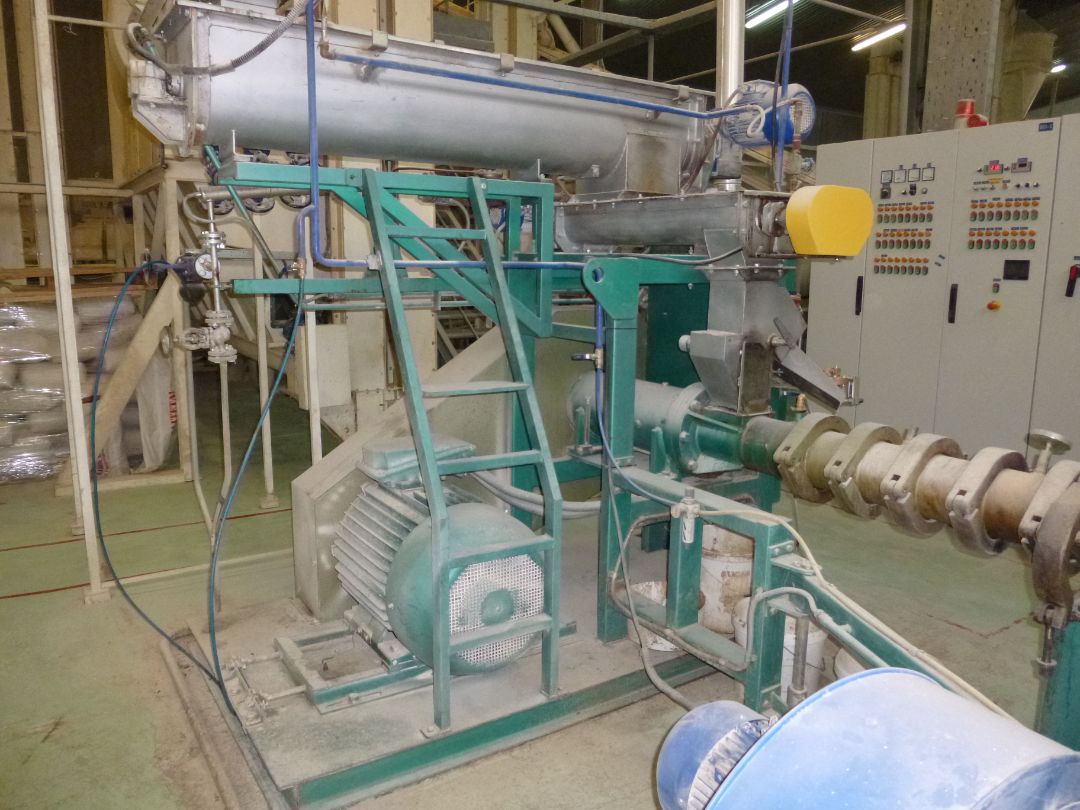

used for production of feed pellets

CherkasyElevatorMash Ltd TM BRONTO

• production of all-in-one feed pellets

EXTRUDER E-1500:

TECHNICAL CHARACTERISTICS:

Capacity: up to 1000 kg/hour

Steam consumption: up to 60 kg/hour

Length: 2400 mm

Width: 2400 mm

Height: 2850 mm

Weight: 4000 kg

POWER: 103 kW

FINAL PRODUCT: EXTRUDED FEED PELLET

for industrial fish, pets, predators

RAW MATERIALS:

soybean meal, sunflower meal, animal components, grains and cereals of wheat, rye, maize, barley, peas, as well as complex mineral supplements and soy flour

EXTRUDER CAPABILITY:

• moisture of the mixture - from 10%

• water input to the mixture - up to 15%

• steam injection into the mixture - up to 6%

• preconditioning of the mixture - up to 3 minutes

• cooling of the screw part of the extruder

OPERATIONAL FLOW OF EXTRUDER:

• Adjustable mixture feed through the feeder / steam lock

• Spraying water into the feed mixture

• Steam input in raw materials

• Mixing and heating

• Retention

• Fat input (up to 2%)

• Loading into the screw part of the feed extruder

• Compressing, mixing and heating the mixture

• Homogenization

• The product is expanded right at the die surface

• Squeezing the feed pellet through the forming die - obtaining the pellets form

• The pellets are cut - obtaining the pellets thickness

Quality assurance:

Warranty period is 1 year

• all machines are certified according to ISO 9001: 2015

• our extruders are designed for continuous and trouble-free operation

ADVANTAGES:

• Improves protein quality in feed

• Provides eatability of all feed components

• Helps regulate feed weight

• Disinfects harmful microorganisms and anti-nutritional substances