MANUFACTURER:

CherkasyElevatorMash Ltd TM BRONTO

Cools the extruded pellet

CherkasyElevatorMash Ltd TM BRONTO

TECHNICAL CHARACTERISTICS:

Productivity: max 1500 kg / h

Inlet temperature: 85 ± 5 ° C

Outlet temperature: 40 ± 5 ° C

Volume of refrigerated product: 1 m³

Length: 1910 mm

Width: 1610 mm

Height: 2510 mm

Weight: 550 kg

POWER: 1.5 kW

All operating modes - set and controlled from the control panel.

FINAL PRODUCT: EXTRUDED FEED PELLET

(inlet temperature: 85 ± 5 ° C)

INPUT MATERIAL: EXTRUDED FEED PELLET

(Outlet temperature: 40 ± 5 ° C)

ADVANTAGES:

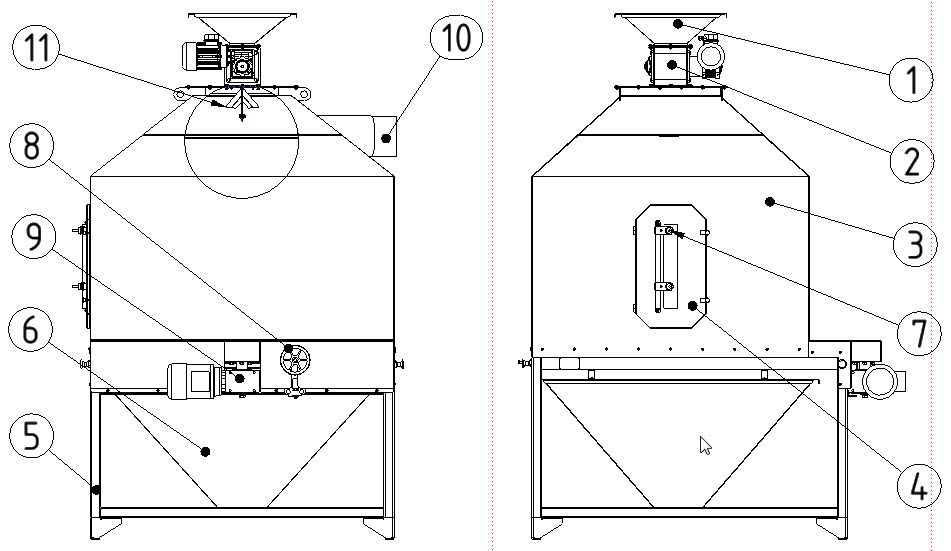

MAIN COOLER UNITS:

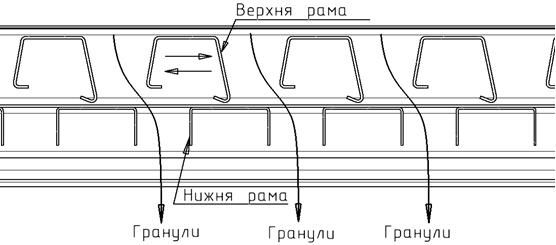

How the product moves:

Quality assurance:

Warranty period - 1 year

• certified production ISO 9001:2015

• Our pellets cooler are designed for continuous and trouble-free operation.